What’s the Difference?

The traditional, flat-bottomed fermenters used by home brewers are rarely temperature-controlled, and many home brewers will skip the secondary fermentation. However, using plastic conical fermentation tanks allows home brewers all of the advantages, accuracy and precision of a commercial brewery with far greater ease.

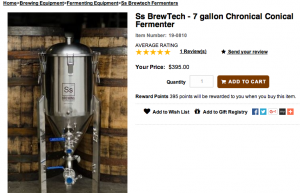

While the basic principles of fermentation are the same, the commercial brewer’s key differences are in the technology used and the processes employed. For many home brewers, the cost of a jacketed stainless steel conical fermenter, not to mention a glycol system and CIP trolley, make it an impractical purchase. However, using a plastic conical fermenter can be a great way to improve your process without a huge outlay.

Fermentation Basics

Fermentation occurs in several stages, but for the purpose of this article, here are the basics.

Primary:

The primary fermentation is when most of the sugars in wort are consumed by yeast and converted into alcohol. This is also when the oxygen is mostly used up and when the yeast multiplies at the most rapid rate. During this stage, the yeast produces many undesirable flavors and odors.

Secondary:

The oxygen and sugars are nearly depleted, and the speed at which your beer will ferment slows right down. If you have a glass fermenter you can actually see less yeast activity, with most of the yeast settled to the bottom of your fermenter. During this stage, the yeast actually starts to clean up after itself; many of the off flavors and aromas are removed.

Lagering:

This is not really a stage of fermentation, but may occur in a fermenter. Lagering is the cold-storage of beer over an extended time to remove the last of the off flavors in the beer. It is not necessary to lager every beer type, but for others it is essential.

Lagering is what gave rise to the beer style known as lager. In German, “lager” means, literally, “to store”.

Yeasting Off

Removing the yeast from your beer as it ferments serves several purposes. For one thing, you can reuse your yeast culture for the next batch. For another, you won’t have the dead yeast continuing to impart off flavors during secondary fermentation. It is also very important to remove the yeast before bottling or kegging for the sake of a cleaner and more presentable beer.

When using a flat-bottomed fermenter, home brewers rely on a process of racking (transferring) their beer from one fermentation vessel to another. Often times this is done with primary fermentation occurring in a plastic pail and secondary being conducted in a glass carboy.

The downside to all of this is the fiddly process, which also requires time, effort, a lot of cleaning, and far too many opportunities for your beer to become infected or aerated (this is bad). In a professional brewery, however, the process of removing the yeast (yeasting off) is much, much easier. At several stages, the yeast from the bottom of a conical fermenter is simply drained off from a tap at the bottom of the cone.

RELATED: How to Filter Beer

Going Conical

For a home brewer, going conical is a huge leap forward in both process and convenience, although it does have certain drawbacks. The price factor is easy to fix though – just go plastic!

Pros:

- All fermentation occurs in a single vessel (no need to rack to secondary)

- Multiple yeast-off during fermentation becomes very easy

- More accurate measurements due to lack of yeast in samples (e.g. hydrometer readings)

- Much easier to harvest yeast

- Easier to clarify beer

- Lower equipment needs

- Seriously cool-looking (this part is important!)

Cons:

- Taller than a flat-bottomed fermenter of similar capacity (requires more storage)

- Slightly harder to clean

- Autolysis – when under pressure (or heat) yeast can start to go cannibalistic and produce off flavors; in batch sizes of under 40 liters/10 gallons this is less of an issue

Where to Get One

A quick Google search can find you a whole range of suppliers offering plastic conical fermenters in all sizes. Just make sure you get HDPE or HDPU – these are high density, food grade plastics.

Brew Demon makes a great range of plastic conical fermenters just for homebrewers, in sizes made for 2 gallons (about 8 liters) or 5 gallons (about 20 liters.) I prefer a 5 gallon batch size, for various reasons – it’s also a fairly standard homebrew size so you’ll be able to find matching recipes and resources more easily.

made for 2 gallons (about 8 liters) or 5 gallons (about 20 liters.) I prefer a 5 gallon batch size, for various reasons – it’s also a fairly standard homebrew size so you’ll be able to find matching recipes and resources more easily.

In the USA you can get a Brew Demon conical fermenter direct from the manufacturer by clicking this link: Brew Like a Pro! Easy-to-use kits and great tasting recipes at BrewDemon.com.

In Canada, you can try Hop Dawgs: Click here.

If you are anywhere else you’ll need to try eBay.

You can get wall mounted conical fermenters from www.homebrewing.org. If you have the spare cash and want a really fancy model, they also stock stainless steel conical fermenters.

Make it Even Cooler

If you are going to start getting really professional with your winning beers, you really need to consider fermentation control. This is a quantum leap from good beer to great beer – and usually what is missing between that one perfect beer you made and every subsequent attempt.

Simply remove the wire racks from a small refrigerator and place your conical fermenter inside, then use a small plug-in thermostat in the power socket and set the desired temperature. Now you are fermenting like a true professional brewer!

Cheers!

For my next article, I may post a how-to guide on making an old refrigerator into a temperature-controlled incubator. For now, please leave any comments or questions below!

Read Next: Proven Ways To Chill Your Beer Fast and All in One: Electric Beer Brewing Systems

Hi Jesse – Great article. Making a good quality home brew must be the dream of every red blooded male (amongst others)

I found your post very enlightening and interesting.

But personally I think you should have a few supplier links to the products you are reviewing.

Great article- Thanks for sharing

Mark

Hi Mark, thanks for commenting.

If you just click on the images you can see, you should get to the websites. I’ll add some more as I find them!

Cheers,

Jesse

This is good for people who like to brew their own beer. But I found your review very realistic and good to read, Am sure the guys will enjoy reading this because I have tasted some home brewed beer before, even though the result was a bit stale because they left it for toooooo long, I still found it tasty. BUt good review.

Thanks Kelly! That is exactly where conical fermenters can have an advantage. Being able to remove the yeast without exposure to outside conditions is a really useful feature.

regarding controlling temperature by customising an old fridge- ive come across this a lot on the web but cant help wonder, given that it seems like a bit of hassle for many people, why arent there many of the shelf, ready to go, temperature controlled fermenters= any reason for this?

Hi Robbo,

It’s a great question, with a simple answer: Using current technology, it’s very expensive! I’ve been playing with a few ideas myself, but so far everything I design is either ineffective, too costly or horrible to use for the home brewer.

If you want a personal project, the world needs a solution to this problem!!